avril 25, 2024

saxhorn euphonium

Actu

Assurance

Banque

Crédits

Finance

Immobilier

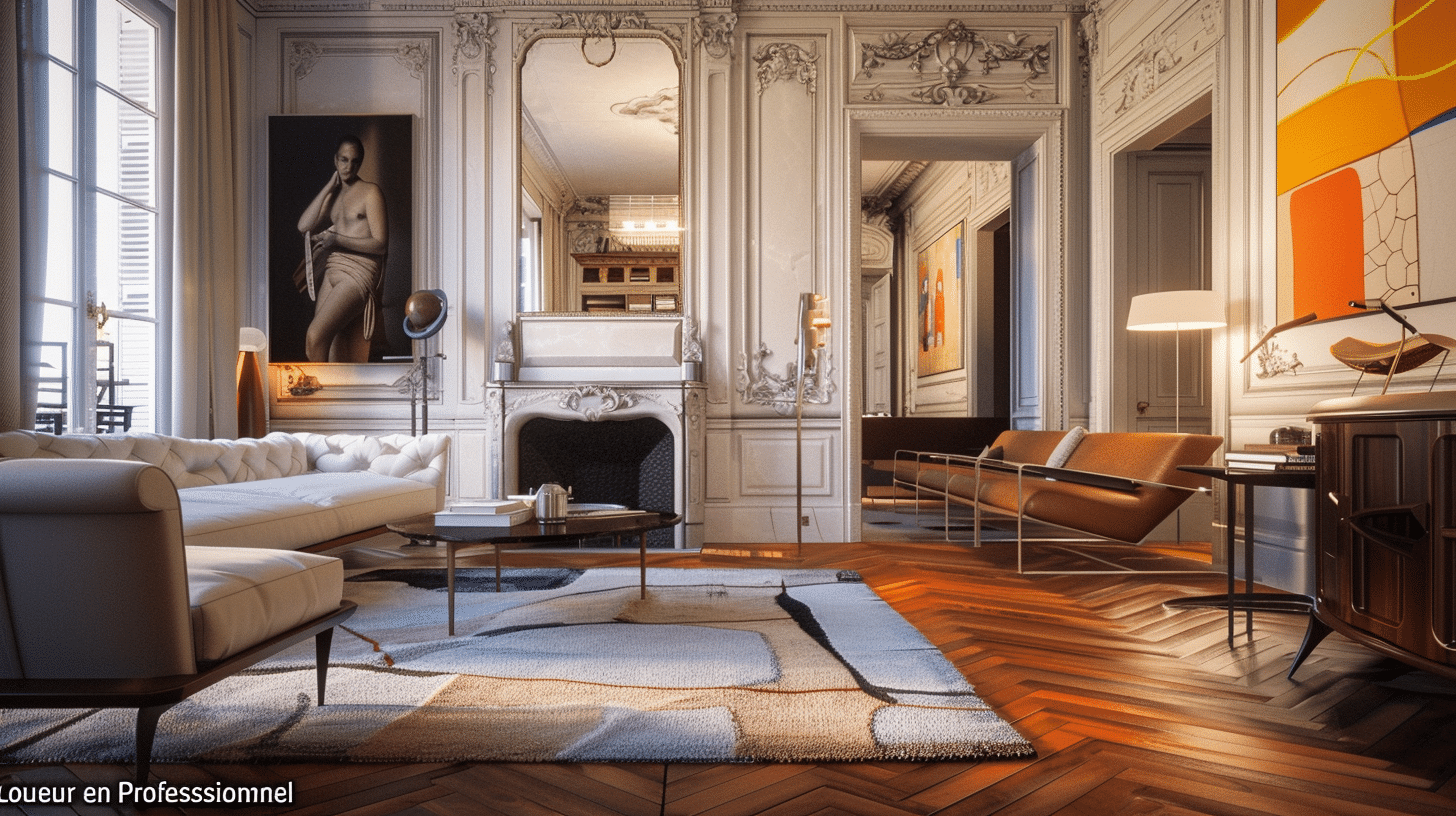

Comment réussir la mise en location d’un appartement meublé ?

Le marché de la location meublée est en pleine expansion et offre de nombreuses opportunités. Pour le propriétaire, c’est une source de revenus supplémentaires et...

janvier 3, 2024

Copyright 2023. Tous Droits Réservés